Electric power is becoming increasingly vital in industry, especially in the logistics and material handling sector. With the growing concern for the environment and operational efficiency, choosing the right forklift battery is crucial. In this article, we’ll explore the different types of forklift batteries, their life expectancies, comparison between lithium-ion and lead-acid batteries, and how to choose the right battery for your needs.

Types of Forklift Batteries

1. Lithium-Ion Batteries

Lithium-ion batteries are revolutionizing the material handling industry due to their various advantages:

Longer Life Expectancy

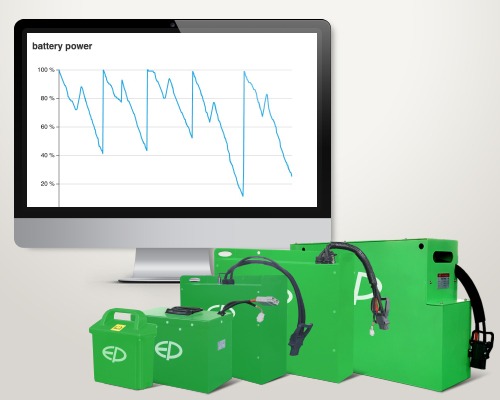

Lithium-ion batteries possess a much longer life cycle compared to lead-acid batteries. With over 3000 cycles, they offer a significantly longer service life, resulting in fewer replacements and reducing operating costs in the long run.

Opportunity Loading

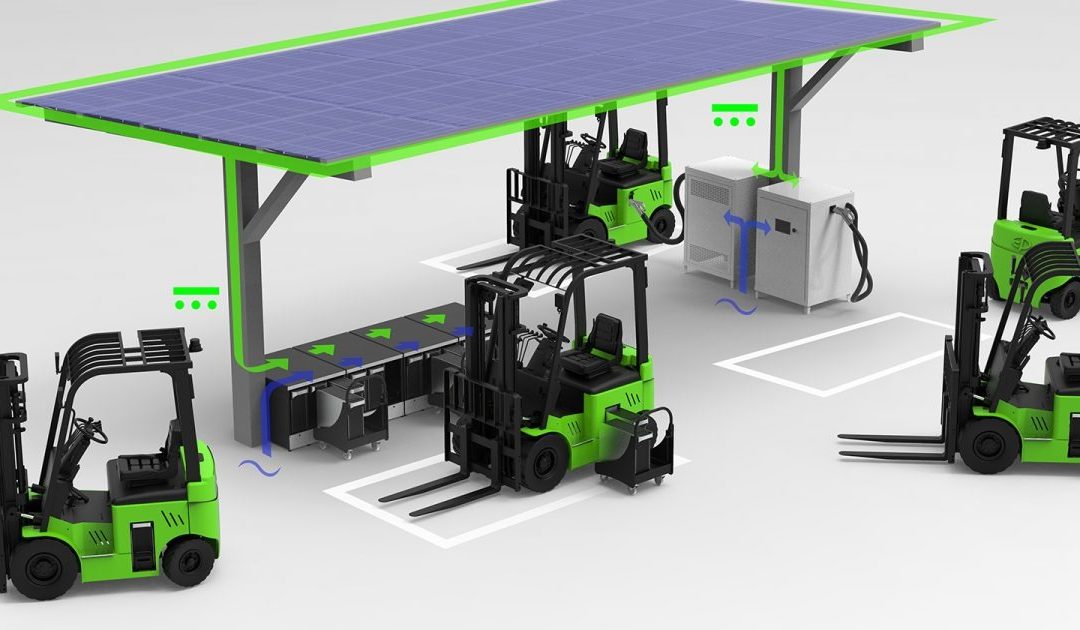

Unlike lead-acid batteries that require full charge cycles, lithium-ion batteries allow for opportunistic charging. They can be recharged quickly during short breaks, such as lunch breaks, reducing downtime and increasing operational efficiency.

Reduced Weight

Lithium-ion batteries are notably lighter compared to lead-acid batteries. Not only does this make it easier to operate the forklifts, but it also allows for more ergonomic and efficient equipment design.

Superior Efficiency

With an efficiency of around 95%, lithium-ion batteries convert a significantly higher amount of stored energy into usable energy compared to lead-acid batteries. This translates into less energy waste and greater operational autonomy.

Faster Charging

Thanks to their high efficiency, lithium-ion batteries can be charged faster. While lead-acid batteries can take up to 8 hours to fully recharge, lithium-ion batteries can be charged in as little as 2-3 hours, significantly reducing downtime.

Friendly to the Environment

Lithium-ion batteries are environmentally friendly as they do not emit toxic fumes and are cleaner compared to lead-acid batteries. This makes them a more sustainable and environmentally safe option.

2. Lead-acid batteries

Lead-acid batteries are more traditional but still widely used in the industry due to their availability and lower initial cost. However, they have some limitations compared to lithium-ion batteries:

Shorter Life Expectancy

Lead-acid batteries typically have a life expectancy of 500 to 1000 cycles, which means they need to be replaced more frequently, resulting in higher operating costs in the long run.

Full Charging Required

Lead-acid batteries require full charge cycles, which can take up to 8-12 hours, increasing downtime and reducing operational efficiency.

Higher Weight

Lead-acid batteries are significantly heavier compared to lithium-ion batteries, which can affect the maneuverability and performance of forklifts.

Lower Efficiency

With an efficiency of around 80 to 85%, lead-acid batteries convert less stored energy into usable energy, resulting in increased energy waste and shorter operating range.

Comparison Between Lithium-Ion and Lead-Acid Batteries

Applications

- Lithium-Ion: Ideal for high-intensity, multi-shift applications where downtime must be minimized, and operational efficiency maximized.

- Lead-acid: It is still widely used in low-intensity applications and single-shift operations due to its lower initial cost.

Charging Options

- Lithium-Ion: Allows for opportunity charging, which means it can be recharged quickly during short intervals.

- Lead-acid: Requires full charge cycles, increasing downtime and reducing operational efficiency.

Space Requirements

- Lithium-Ion: Due to their reduced size and weight, lithium-ion batteries take up less space and offer greater design flexibility.

- Lead-acid: They are bulkier and heavier, taking up more space and limiting the design of the equipment.

Life Expectancy

- Lithium-Ion: It has a longer life expectancy of over 3000 cycles, reducing long-term maintenance and replacement costs.

- Lead-acid: It has a shorter life expectancy, with only 500 to 1000 cycles, resulting in higher operating costs in the long run.

Costs

- Lithium-Ion: Although they have a higher initial cost, lithium-ion batteries offer greater long-term savings due to their longer lifespan and lower maintenance requirements.

- Lead-acid: It has a lower upfront cost, but the long-term operating costs, including maintenance and replacement, can be significantly higher.

Performance

- Lithium-Ion: It offers increased efficiency, faster charging times, and greater operating autonomy, making it ideal for high-intensity operations.

- Lead-acid: It has lower efficiency, slower charging times, and shorter operating autonomy, making it more suitable for low-intensity operations.

How to Choose the Right Battery for Your Forklift

When choosing the right battery for your forklift, consider the following factors:

Type of Application

Determine if your operation requires a high-intensity battery, such as lithium-ion, or if a lead-acid battery will meet your needs.

Operating Costs

Evaluate the long-term operating costs, including maintenance and replacement costs, to determine the most cost-effective option.

Efficiency and Performance

Consider the efficiency and performance of batteries in terms of charging time, operating range, and energy efficiency.

Available Space

Consider space and weight requirements when choosing between lithium-ion and lead-acid batteries.

Choosing the right battery for your forklift is essential for optimizing operational efficiency, reducing costs, and minimizing environmental impact. While lithium-ion batteries offer several advantages, including longer lifespan, shorter charging times, and increased efficiency, lead-acid batteries are still a viable option for low-intensity applications due to their lower initial cost. By considering your specific needs and the requirements of your operation, you can make an informed decision about which type of battery is best for your forklift.

For more information about EP Equipment’s lithium-ion batteries and how they can benefit your operation, contact our representatives today.