In the modern world we live in, forklifts handle almost every good that we consume. With the cost of living increasing globally, the initial price of material handling equipment is a huge factor in decision-making when buying a forklift truck. However, when it comes to choosing the right forklift for your business, it’s essential to consider more than just the upfront costs.

If you’re considering an investment in forklift trucks for your rental fleet or business, the total cost of ownership should be a leading factor in your decision.

In previous years forklift ownership costs were in favor of IC engine Trucks, but with modern developments in electric forklift technology and the introduction of lithium-ion forklifts, the decision to go electric has become popular around the world.

What is an IC Forklift?

The material handling industry sees forklifts classified into two main categories: electric and internal combustion (IC). Internal combustion models are powered by hydrocarbon fuels such as diesel, liquefied propane gas (LPG), liquid gasoline or petrol, and compressed natural gas (CNG). Traditionally IC forklifts are considered to be better suited to heavy duty and outdoor handling applications.

The Cost of an IC Forklift

Traditionally, IC Forklifts are thought to be cheaper than their electric counterpart. However, in recent years, products like EP Equipment’s EFL Series have made electric forklift trucks more accessible with lithium-ion batteries in an IC chassis at an affordable price.

This introduction of lithium-ion battery forklifts has highlighted further the ongoing costs of IC trucks. These can be eliminated by going electric.

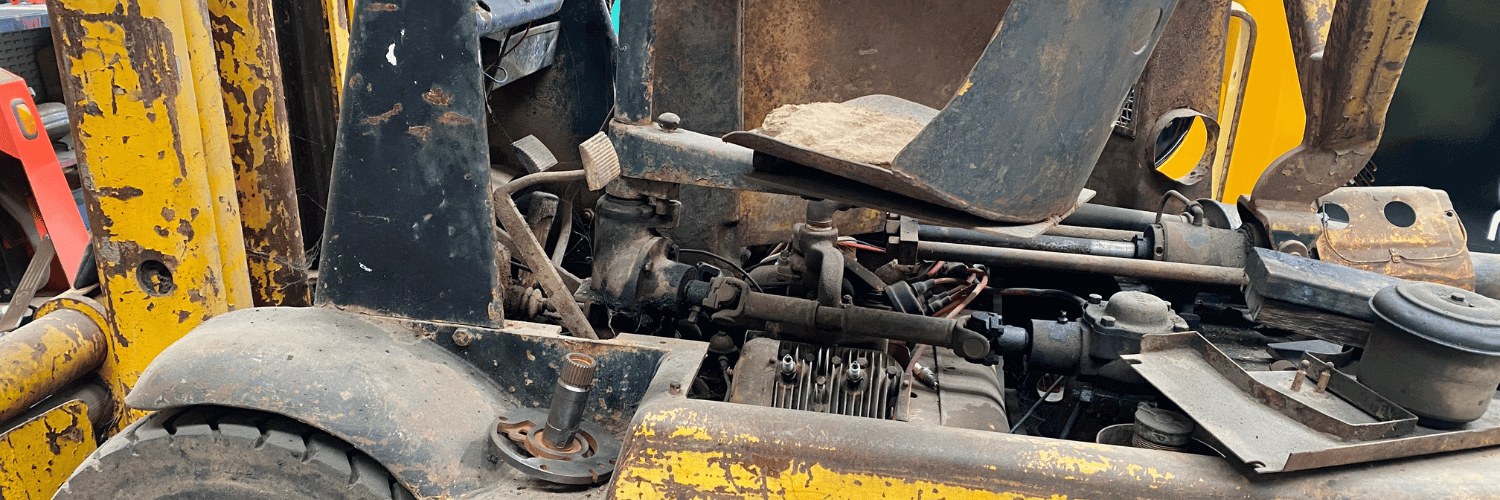

Hidden costs of IC Forklifts include:

1. Engine Oil and Filters:

Frequent oil changes are necessary for IC forklifts at a frequency of 250 hours of use, costing approximately €70. An extra €20 expenditure is necessary for oil filter replacements. A benefit of electric forklifts is that they do not need engine oil.

2. Air Filters:

IC forklifts require air filter replacements every 500 hours or annually, this costs around €30 per filter. With electric forklifts, there’s no internal combustion engine, so no air filter maintenance!

3. Fuel Filters:

Fuel filters protect the IC engine from fuel contaminants and must be replaced every 500 hours, costing €25 per filter. Electric forklifts do not require expensive fuel or filters and operate on electricity alone.

4. Spark Plugs:

IC forklifts with gasoline or propane engines need spark plug replacements every 1,000 – 1,500 hours, costing €15 per spark plug. Electric forklifts don’t have spark plugs, meaning you can check another maintenance item off the list.

5. Hydraulic Fluid and Filters:

IC forklifts require hydraulic fluid changes every 2,000 hours or annually, costing around €140. Hydraulic filters should also be replaced, adding another €30 per filter. Electric forklifts also require hydraulic fluid changes, but the absence of an engine means less contamination, so less frequent changes!

6. Tires:

Although both IC and electric forklifts require tire replacements, IC forklifts typically have higher fuel consumption and increased emissions, leading to greater wear and tear on tires. Tires can last up to 3,500 hours, costing a total of€460 per tire.

7. Planned Maintenance (PM) Program:

A PM program for IC forklifts includes routine inspections, lubrication, and adjustments, costing €270 per visit. Electric forklifts have fewer components, which means less maintenance and lower PM costs!

The high costs associated with IC forklift maintenance, along with their environmental impact, make electric forklifts an attractive alternative. Investing in electric forklifts means lower long-term expenses and a smaller carbon footprint!

Lithium-ion forklifts also have a number of other benefits that can influence your decision in the battle of IC vs electric.

What Are The Maintenance Costs Of Lithium-ion Forklifts

The maintenance costs of lithium-ion forklift trucks are lower compared to other types of forklifts.

1. Reduced Maintenance Requirements

Lithium-ion forklift trucks have fewer moving parts compared to IC forklifts, which typically have complex engines, transmissions, and exhaust systems. The simplified design of lithium-ion forklifts leads to fewer components that require regular maintenance. There is no need for oil changes, filter replacements, or engine tune-ups, resulting in reduced maintenance tasks and associated costs.

2. Elimination of Fuel-Related Maintenance

Unlike IC forklifts that rely on gasoline, diesel, or propane, lithium-ion forklifts do not require fuel. This eliminates the need for fuel-related maintenance tasks, such as fuel system inspections, carburetor adjustments, or fuel filter replacements. By eliminating these maintenance requirements, businesses can save on labor costs and reduce the frequency of maintenance schedules.

3. Extended Battery Lifespan

While lithium-ion forklifts have batteries that require periodic maintenance, the intervals are typically longer compared to the maintenance needs of IC forklift engines. Lithium-ion batteries are known for their durability and long lifespan. They can handle a high number of charge and discharge cycles without significant degradation. Additionally, advanced battery management systems within lithium-ion forklifts help prevent overcharging and overheating, further extending the battery’s lifespan.

4. Simplified Charging and Battery Management

Lithium-ion forklifts generally have simpler charging requirements compared to other electric forklifts. They often feature fast-charging capabilities, allowing for quick charging during breaks or shift changes. The advanced battery management systems mentioned earlier help optimize the charging process and ensure efficient use of the battery’s capacity. With streamlined charging processes, there is less need for complex maintenance procedures related to battery charging.

5. Limited Fluid and Emission Management

IC forklifts require regular maintenance tasks related to fluids such as oil, coolant, and hydraulic fluids. These fluids need to be regularly checked, changed, or topped up, adding to the maintenance costs. In contrast, lithium-ion forklifts have sealed battery packs and do not require fluid management. This reduces the maintenance tasks associated with fluid inspections and replacements.

Additional Benefits of Lithium-ion Forklifts

Zero Emissions and Environmental Sustainability:

One of the most significant advantages of Lithium battery forklifts is their zero-emission operation. Unlike IC forklifts that rely on fossil fuels, Li-ion forklifts run on electricity, resulting in zero exhaust emissions. By eliminating greenhouse gas emissions and harmful pollutants, businesses can contribute to a cleaner and healthier environment. This aligns with sustainability goals and positions companies are increasingly having to act under around the world.

Lower Operating Costs:

Li-ion forklifts offer notable cost advantages compared to IC forklifts. They have higher energy efficiency, meaning they require less energy to operate and can run for longer periods on a single charge. This translates into lower electricity costs for businesses, ultimately resulting in substantial savings over time.

Moreover, Li-ion forklifts have significantly reduced maintenance requirements. IC forklifts involve regular maintenance tasks such as oil changes, filter replacements, and engine tune-ups, all of which can be time-consuming and costly. In contrast, Li-ion forklifts have fewer moving parts, eliminating the need for frequent maintenance and reducing associated costs. This results in reduced downtime and higher productivity.

Improved Performance and Productivity:

Li-ion forklifts provide improved performance and greater output, leading to better operations and increased effectiveness. Their ability to provide consistent power throughout the battery life ensures optimal results until the power runs out.

In contrast to this, IC forklifts lack this capability and lose power as the fuel level drops, resulting in lower performance. Additionally, Li-ion forklifts have quicker acceleration and more maneuverability, allowing for instant torque and fast response times, so operators are able to move materials quickly and competently. This is especially useful in busy warehouses where speed is essential.

Increased Safety and Operator Comfort:

Safety is paramount in any workplace, and Li-ion forklifts prioritize operator well-being. They produce less noise and vibration compared to IC forklifts, leading to a quieter and more comfortable work environment. Reduced operator fatigue contributes to enhanced concentration and alertness, minimizing the risk of accidents.

Li-ion forklifts also eliminate the hazards associated with handling and storing flammable fuels, reducing the risk of fires and spills. With no fuel emissions, there is improved air quality within the facility, creating a healthier atmosphere for both operators and other employees.

Longer Lifespan and Durability:

A factor that can also influence the electric forklift cost is that Li-ion forklifts generally have a longer lifespan compared to IC forklifts. They have a high cycle life and can withstand frequent charge and discharge cycles without significant battery degradation. This results in fewer battery replacements over the lifetime of the forklift, reducing long-term costs.

Furthermore, Li-ion forklifts are built with advanced battery management systems that prevent overcharging and overheating, ensuring the longevity of the battery. This robust construction and durability contribute to a more reliable and cost-effective forklift solution.