High Voltage Series

High Voltage

Counterbalance Electric Forklift

4-25T

Why High Voltage?

High Performance: High Speed & High Gradeability

100%

Improvement in travel speed for high voltage models in laden and unladen conditions.

45%

Faster lifting speed demonstrated by the high-voltage models.

45%

Improvement in gradeability when laden for high voltage models.

100%

Improvement in gradeability when unladen.

Energy Efficiency: Extended Runtime & Fast Charging

At the heart of EP’s new series is a focus on cost savings through energy efficiency. EP’s lithium-ion trucks deliver:

- Lower Energy Consumption:These high-voltage models use up to 15% less energy with PMS motors and lithium-ion batteries.

- Extended Battery Life & Reduced Downtime: Batteries last up to 4000 cycles, reducing maintenance and replacement costs.

- Rapid Recharging: The high-voltage models are compatible with vehicle-grade charging stations and support 1C charging rating, allowing them to be fully charged in as fast as 1-1.2 hours.

1C

CHARGING

1 HOUR

FULLY CHARGED

15%

ENERGY SAVINGS

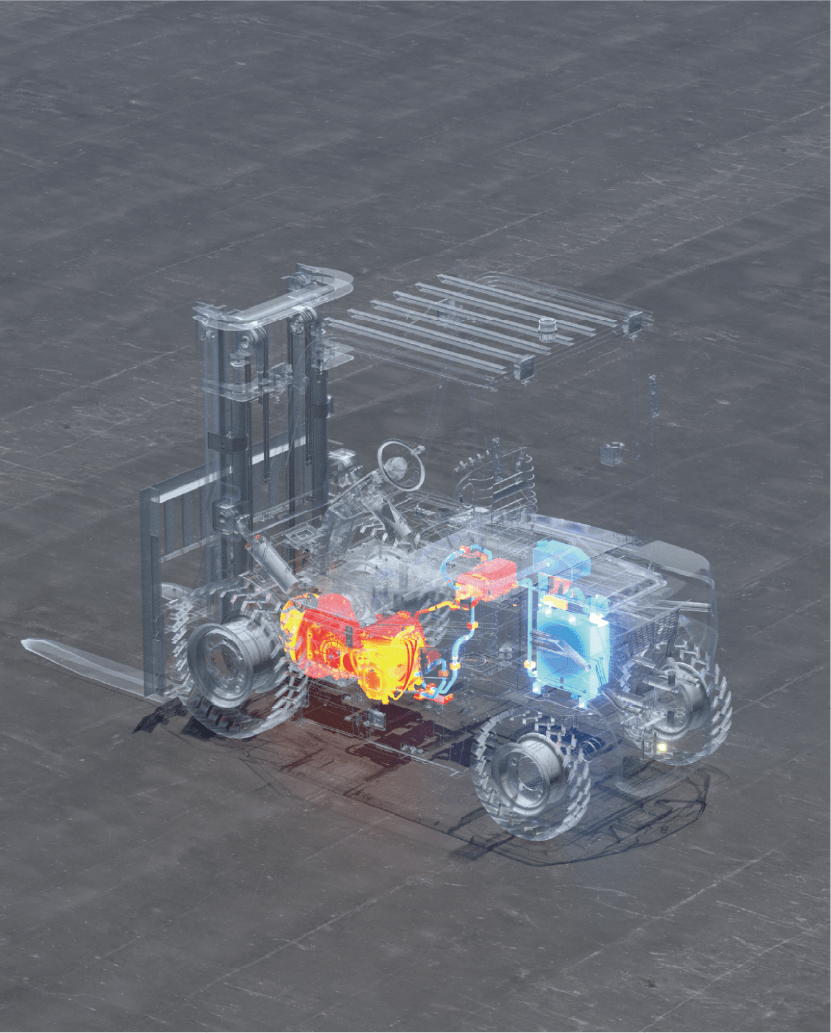

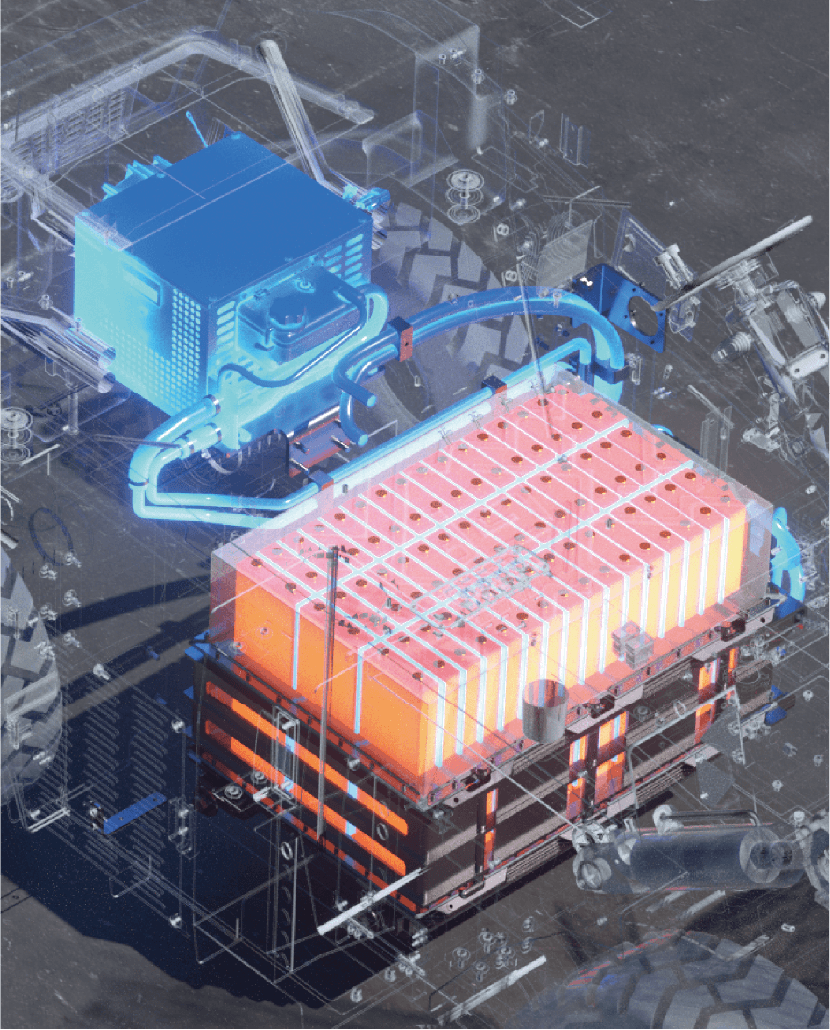

Smart and reliable strategy for thermal management

- Cooling for motors, maintaining an optimal temperature range of 30-35°C.

- Water cooling system protecting battery components from thermal stress and ensuring consistent performance.

- Oil cooling system for hydraulics, preventing overheating during intensive operations.

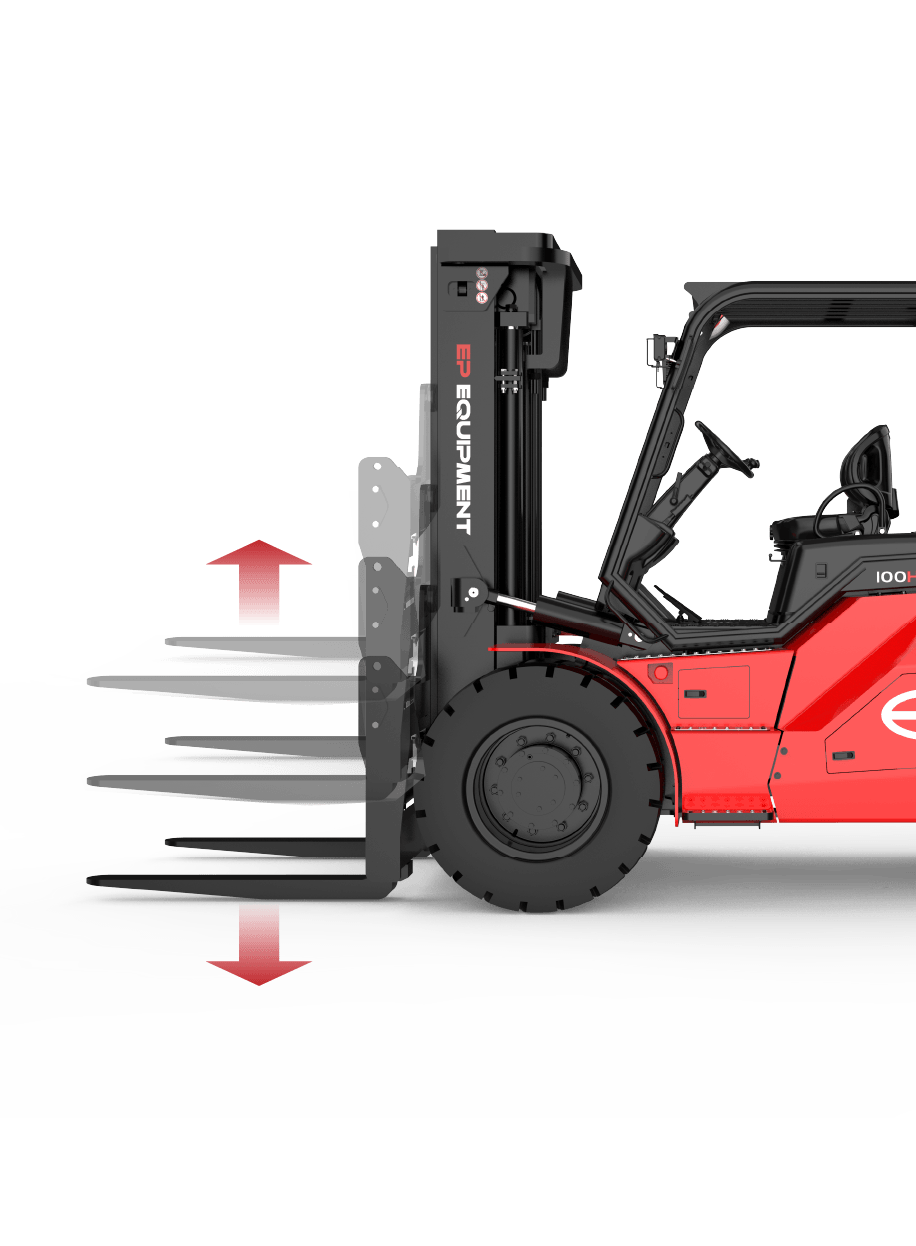

- Intelligent Speed Control: For increased stability, especially during turns, intelligent speed control adapts based on load weight, preventing unexpected shifts or imbalances. The hydraulic buffering system in the mast ensures smooth load handling, protecting cargo integrity and providing a comfortable experience for operators.

Innovation in Safety and Operator Comfort

EP Equipment prioritizes safety and operator’s comfort without compromise, integrating advanced features into every aspect of the new li-ion series:

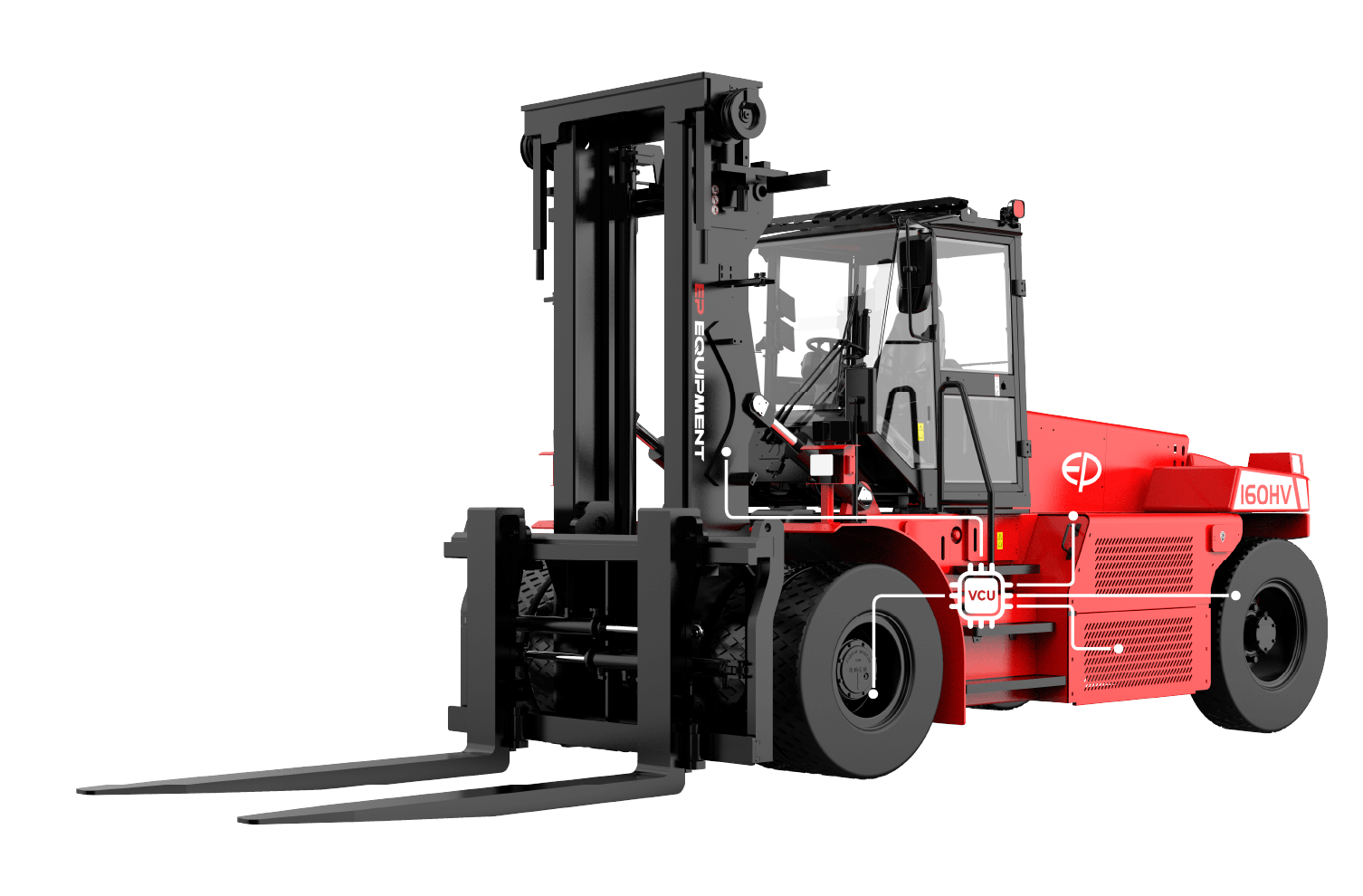

- Comprehensive Battery & Motor Protection: Trucks designed with a Vehicle Control Unit (VCU) offer real-time monitoring and precise control of critical parameters. This allows for quick adjustments based on the truck’s status, enhancing both operator safety and overall reliability.

Low maintenance: Longer battery life span

- Longer Battery Life: Lithium-ion batteries last 4000 cycles, reducing replacements, while PMS brushless motors lower maintenance costs.

- Simplified Maintenance with the Battery Management System (BMS): The advanced BMS monitors battery status, ensuring stability and extending battery life with fewer interruptions.

- Emissions-Free Performance: No carbon monoxide, nitrogen oxide, or hazardous acid spills.

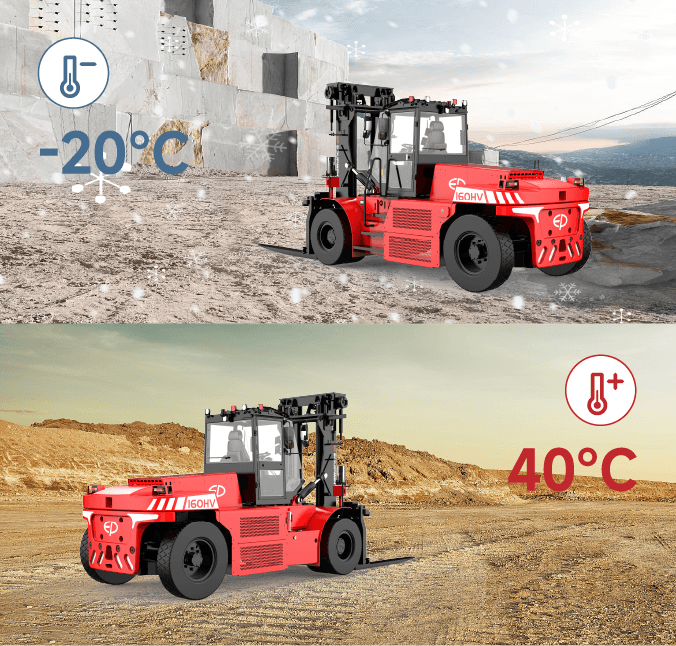

Strong adaptability adaptable to harsh outdoor weather conditions

With durability at the forefront, EP’s new trucks are tailored to meet the challenges of demanding industrial settings:

- All-Weather Resilience: Rated IPX4 for overall protection and IP67 for high-voltage components, these trucks operate from -20°C to 40°C, with battery heating for efficient cold-weather charging.

- High Stability in Outdoor Environments: Dual front wheels on most models ensure stability on uneven or slippery surfaces.

- Adaptability to Multiple Industries: From lightweight models for tight spaces to heavy-duty versions for construction and mining, these trucks offer reliability, enhanced gradeability, and optional attachments for diverse applications.

Comprehensive Support and Telematics for Enhanced Productivity

Real-Time Telematics

EP’s telematics system monitors truck status, battery conditions, and performance, helping schedule maintenance to reduce downtime and boost fleet efficiency.

Around-the-Clock Assistance

EP’s global support team, including production and technical experts, provides 24/7 virtual assistance and swift spare parts delivery.

Training and Resources

EP offers operator training programs to ensure safe, efficient truck use, backed by comprehensive support for long-term reliability.

Unique

The HV series combines advanced power technology with robust performance, offering businesses an efficient and sustainable option for their material handling requirements.