Forklift Maintenance is an important cost factor in the TCO of a forklift or any industrial machine. When considering forklift rental or forklift truck purchase, it is important to have an understanding of how to maintain the machine in-order to operate safely and efficiently. The level of forklift maintenance varies across different types of forklift trucks with some having significantly higher maintenance requirements than others.

In general, 2 categories of forklift truck to consider are: Internal Combustion (IC) Forklifts, including Gas Forklift and Diesel Forklift, and Electric Forklifts, including Lead Acid Forklift and Lithium Ion Forklift.

IC Forklift

The highest maintenance costs will be seen with the diesel forklift and the Gas forklift trucks, as the internal combustion motor needs regular maintenance and there are more wear and tear parts on these machines. In addition to this, the factor of oil filters, exhaust filters as well as regular checks on the engine will increase the maintenance and service costs of these machines. Traditional electric counterbalance trucks reduce the maintenance cost already significantly compared to IC.

How do I maintain an IC forklift?

Engine Maintenance

Minor maintenance includes:

- Release pressure by removing filler caps

- Change engine oil and oil filter

- Top up your engine coolant

- Clean the engine cooling system the air filter

- Inspect drive or fan belt

- Check the fuses and hoses

- Refuel

- Add AdBlue

- Bleed the fuel system

- Checking and refuelling LPG

- Tighten the cylinder head bolts

- Adjust engine idle speed and ignition timing

Intermediate maintenance includes:

- Change the fuel filter or clean the LPG filter

- Check and adjust valve clearance if necessary

- Replace the spark plugs for gas and petrol machines

- Drain the water separator and clean the radiator

- Clean the radiator exterior and replace the fuel filter

- Make sure you replace the points, the condenser and the set timing

Major maintenance includes:

- Replace the coolant

- Check and replace fuel filter, fuel strainer element and water separator

- Replace the distribution belt and other seals such as the gasket seal

- Clean or replace the interior ventilation filter

Electric Forklift

Electric powered forklifts don’t need as much maintenance as those powered by internal combustion engines. That’s because there are fewer parts to maintain. The mechanics of an electric counterbalance are much simpler, but, of course, they still need to be inspected to make certain that everything is in good working condition. The operator or technician will need to check the battery to make certain that it has the proper water/electrolyte level and that it is charged properly

How do I maintain a lead acid forklift?

Lead Acid Battery Maintenance

On a lead acid battery truck, the maintenance of the machine itself is reduced heavily as the wear and tear parts are less and the number of filters that need to be changed is reduced to a minimum.

The major after sales and maintenance costs on a lead acid truck come from the battery. The battery must be regularly checked for the acid level, the water level must be checked regularly and refilled with distilled water.

In addition to this, lead acid batteries bare some operational risk. They are only allowed to be charged in specially equipped charging rooms with air circulation. This is because during the charging process, the trucks are emitting gas that has potential to cause an explosion when exposed to a small spark.

Weekly maintenance tasks:

- Clean the battery

- After charging, top up the cells with ionised water

- Check the electrolyte levels

- Perform an equalisation charge

Minor maintenance includes:

- The Battery

- Replace the battery if damaged

- Check the temperature of the connections

- Tighten loose battery bolts

- Maintain oxidised battery bolts

- Check the connectors and cables for damage, burning or corrosion

- Clean the top of the battery housing

- Measure the gravity of the electrolyte

- Secure the hood latch

Intermediate maintenance includes:

- Clean the battery thoroughly

Charger maintenance include:

- Inspect cables, micro-switches and connectors for wear and damage

- Inspect AC and DC fuses

- Clean and ventilate charger cabinet

- Blow out circuit boards with high pressure air

What is the best forklift battery?

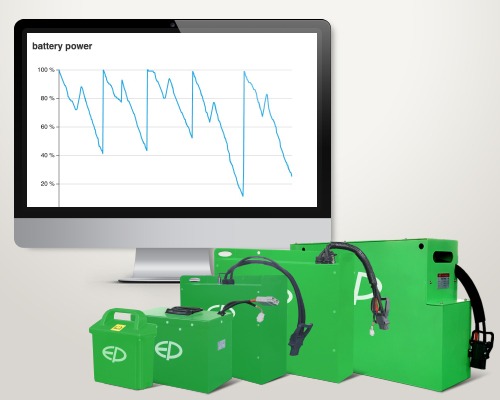

Lithium-Ion Battery Maintenance

Lithium-Ion counterbalance trucks are considered maintenance free and do not require cleaning, watering or equalised charging like lead acid trucks with the same capabilities.

The Battery

- None Required

Lithium-ion Charger Maintenance

- A lithium-ion battery charger should be cared for and maintained to the same standard as a lead acid charger as detailed above.

EP Equipment’s range of maintenance free forklift trucks can be found here.

General Forklift Maintenance

How do you maintain a forklift truck?

Forklifts require a general level of basic maintenance regardless of whether they are IC or Electric. This maintenance requires inspection of all parts of the truck to ensure the forklift is in safe and working condition.

Tyres

Regular inspection of tyres for damage or change in wheel shape and ensuring they have the correct pressure (if necessary) and appropriate tread depth is very important in order to operate safely.

Forks

Forks should be checked for correct fitting and inspected for wear and cracks.

The Hydraulics

The hoses and hydraulics and seals should be inspected for leaks and the oil quality and levels should be checked and maintained. In addition to this the up keep of the pump, filter and cylinders is very important.

Mast

Masts must be checked to ensure that all nuts and bults are tight and the tighten loose nuts and bolts as well as correctly lubricated for lifting. It should be ensured that over time the mast chains and pulleys are not showing excessive wear and replacements should be made accordingly.

Brakes

Check if the brake pedal and handbrake work correctly and keep brakes in clean working order. Brake fluid should be changed and the brake pads and other components should be monitored for wear.

The Chassis

The chassis of the truck should have the steering and transmission regularly checked and close attention should be paid to any warning lights displayed by the truck. The chassis should be well maintained, and suspension rubber should be monitored.

Accessories

Are the lights, horn and seatbelts working correctly.

By following a maintenance plan that caters for the specific requirements of the forklift you can protect your employees, machine and business from harm and encourage a safe and efficient workplace environment. By keeping up with maintenance you can reduce damage and cost requirements for your machine through preventative methods and reduce bigger more expensive damage.