JD. com is China’s largest online retailer and a member of the Fortune Global 500. Aimed at offering customers the best online shopping experience, JD. com founded its own logistics department in 2007 and continued to develop it with a similar strategy to US tech group Amazon’s logistics arm, leading to the establishment of JD Logistics in 2017.

JD Logistics contributes itself to providing smart supply chain and logistics services to businesses across a wide range of industries. As of 2021, JD Logistics has operated 32 “Asia No. 1” automated smart logistics parks and leveraged a network of over 1,000 warehouses with a total of over 21 million square meters. With this list of accomplishments under their belt, JD Logistics was listed on the Hong Kong Stock Exchange in May 2021.

As one of the busiest logistics centers in the country, the Central China region of JD Logistics takes care of all the package deliveries across four provinces: Hubei, Hunan, Henan, and Jiangxi.

There are 8000 units in total of material handling equipment working in this region. This includes electric counterbalance trucks with clamps to move around larger parcels like household electrical appliances, reach trucks for vertical stacking in warehouses with high racks over 8 meters, forklifts for the loading and unloading of lorries, electric pallet trucks to transfer parcels in the warehouses and electric stackers for stacking parcels in operating departments.

Among all equipment, there are 2,500 units of EP trucks, including li-ion pallet trucks, stackers, reach trucks and li-ion forklifts.

In addition to the Central China region, the South and East China regions of JD Logistics have also signed a long-term rental contract with EP for over 400 units of electric pallet trucks. In total, EP supplies 30% of the equipment JD Logistics acquired, making it the major supplier partner among all global brands such as Linde, Jungheinrich, Heli, Hangcha, and BYD.

What Concerns JD Logistics Most When Choosing Material Handling Equipment?

Purchasing Department Manager Shao Xing told the EP team “JD Logistics has been searching for the most cost-effective way to achieve increased efficiency when delivering”. The team at JD has identified that their greatest challenge in delivering all the packages to their customers in time is the high costs of labor and the difficulty of maintaining the equipment.

“Expenses on employment is our biggest investment. We need 5,000-6,000 employees to manage the daily routes on regular days while during JD’s biggest online shopping festival, 618, the demand on employees rapidly increases up to 13,000.”

(JD Logistics preparing for the biggest online shopping festival, 11.11 with RPL201 standing by, 2019)

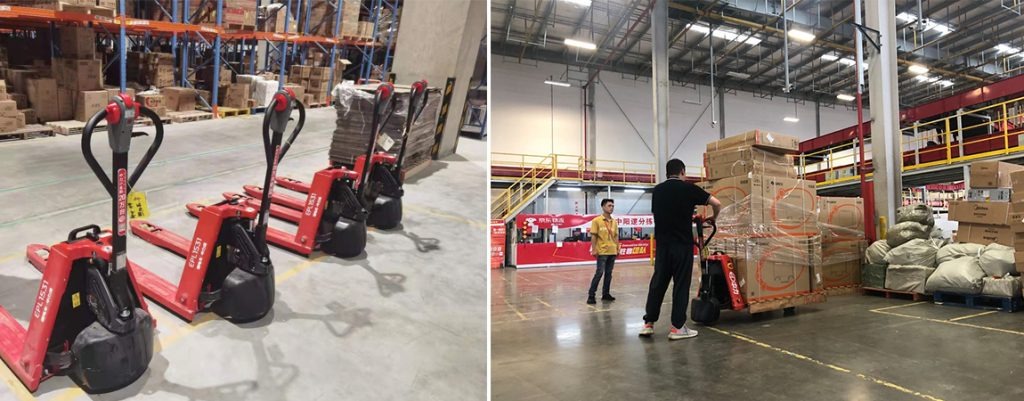

To cut down the spending on material handling equipment while still allowing for the use of the machines around the clock with high efficiency, JD Logistics intended to purchase batches of EPT20-20RA with extra batteries.

This is a lead-acid ride-on pallet truck and does not have the enticing benefits of lithium-ion power. The inconvenience of battery topping changed the mind of the JD team. Soon after an order was placed for 76 units of the RPL201, EP’s li-ion pallet trucks, perfect for the applications required in the transshipment center in Zhengzhou.

“Our pallet truck operators have no idea how to water the lead-acid battery and sometimes their incorrect methods cause damages to the trucks. The li-ion batteries of RPL201 are maintenance-free and save us a lot of worries.

At first, we thought that li-ion trucks could not sustain a 20-hour working day via a 3-shift pattern with its peak between 7pm and 5am, but the fact is that these trucks can do opportunity charging and can be fully charged during even one-hour break. We’re impressed that these trucks can always be on duty with hardly any downtime.”

EP Equipment Li-Ion Trucks at JD Logistics

As the biggest crowdsourcing logistics in the Henan province, Jingxi in Zhengzhou mainly delivers small-sized parcels such as personal care products, fresh food, and other daily necessities to 51 cities nearby.

Founded 7 months ago, the throughput of Jingxi has tripled to hundreds of thousands of pieces a day due to the RPL201 they purchased from EP just three months ago. The switch from hand pallet trucks to electric pallet trucks has saved 2 to 3 handlers working at the loading docks, greatly improving the working efficiency and safety of the operators.

“This truck is easy to use with the electric steering function. Previously, I was only able to move around 100 pallets per night using the hand pallet truck but now I can move around 300 pallets per night with the help of this truck. People from other departments also want to use this truck and borrow it from time to time” – a JD operator interviewed on-site.

The transit station in Wuhan is the center of the Central China region of JD Logistics with over one million parcels handled per day. Packages coming from four provinces arrive here to be sorted on the conveyor belt and then leave for their destinations.

Packages that are off the belt will be sorted again and transferred to the right branch and this is when the EPL153(1) has changed the game. Taking the place of ride-on lead-acid pallet trucks, the EPL153(1) saves a great deal for JD Logistics on the cost of handling equipment and wins unanimous praise from the staff.

“Using this truck needs no operation training at all, anyone is able to be familiar with it after 3 minutes, it’s perfect for some of our colleagues and part-timers who have limited experience with technology to operate. The plug&play lithium ion battery is very convenient to charge and needs no maintenance.”

EP Equipment Ride-on Li-Ion Pallet Truck for Rental

In order to cope with the delivery volume of 51 districts and cities within Henan province, Jingxi itself took charge of the shipment but had to add 8 smaller logistics companies to aid with the delivery. Ride-on pallet trucks are rented for reloading and getting goods ready for their final destinations. Two of the small logistics companies rent EP’s RPL201 to reduce the burden of moving 100-200 pallets around one night.

“When I drive this li-ion pallet truck, I feel very comfortable with the steering system. And unlike other brands, the cargo on this truck never falls. Safety is more important than speed.”- said the operator from one of those smaller logistics companies.

Why JD Logistics Chooses EP Equipment as the Li-Ion Truck Supplier?

With continuous product improvements to better adapt to the real applications of JD Logistics, and responsive after-sales services to keep the machine operating smoothly, EP Equipment won the trust of JD Logistics. Moreover, EP technical support team regularly offers on-site training on operation safety and maintenance to equip local operators with more truck knowledge. Therefore, EP Equipment has become the corporate supplier partner since August 2020.

In addition to JD Logistics, EP Equipment also services other top Chinese domestic logistics companies like SF Express, YTO Express and STO Express. This means EP Equipment is operating in businesses that are occupying 30% of the logistics market in China.

Expectations for Further Cooperation

In the future, EP Equipment will continue to provide state-of-art products that best serve JD Logistics needs with self-developed lithium-ion technology. If trends continue, EP’s AI service (available when needed) on the autonomous mobile robots will improve their operational efficiency and require less hands-on labor that can be utilized elsewhere in the factory.