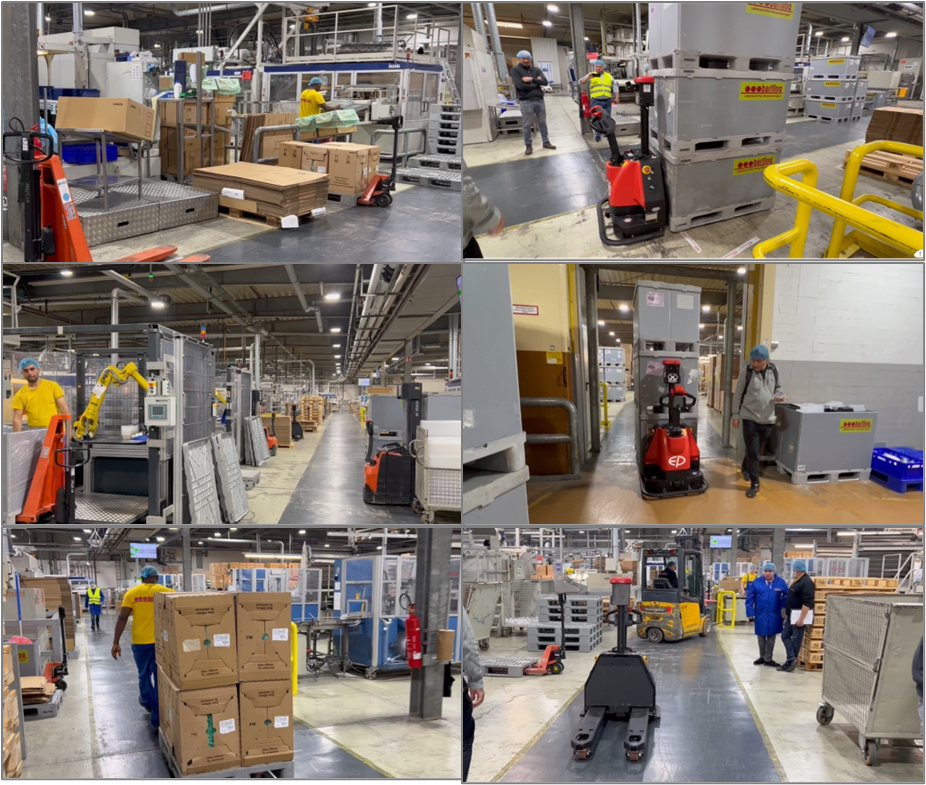

With a fast-paced logistics and manufacturing environments, and constant lack of labours, automation has become a key strategy.

What is an AMR?

An Autonomous Mobile Robot (AMR) is a type of robot that navigates and transports materials within a facility without direct human control. AMRs, like XP15, rely on intelligent navigation systems, such as 2D navigation and Bluetooth connectivity, to move through dynamic environments. Unlike traditional automated guided vehicles (AGVs), which follow fixed paths, AMRs can adjust their routes and operate independently, providing extra flexibility.

XP15 makes AMR technology accessible, for smaller warehouses and businesses with limited budgets.

Why Choose the XP15 for Warehouse Automation?

The idea of automating warehouse processes can seem overwhelming—often due to high costs, long implementation times, and complex IT requirements. But XP15 changes the game with its cost-effective, easy-to-implement (within 1 day) design that requires no extensive infrastructure. Starting at just €500/month, XP15 delivers the benefits of automation at a price point accessible to any warehouse.

Key Features of the XP15 AMR

XP15 comes with many innovative features, here’s what makes it stand out:

- Affordable Price Point: Starting at €500/month, the XP15 is one of the most budget-friendly options for companies seeking to add automation without heavy upfront costs.

- Automated Pallet Transport: The XP15 automates the repetitive task of moving pallets, from picking up loads to returning to its starting point after each task, freeing up staff for more valuable work.

- Easy Setup with Bluetooth and 2D Navigation: With a 2D navigation system and Bluetooth connectivity, routes and tasks can be set up and modified within a single day.

- Flexible Upgrades: For businesses looking to scale, the XP15 offers options to upgrade to M2M communication, WiFi control, and Warehouse Management System (WMS) integration as needed, ensuring that the XP15 can grow alongside your operations.

- High Load Capacity: XP15 has a load capacity of 1500kg, handling heavy loads with ease.

How XP15 AMR Improves Warehouse Operations

Implementing XP15 in your warehouse has immediate and long-term benefits, including:

- Labor Efficiency: By taking over the manual transport of pallets, the XP15 frees your staff from repetitive tasks, allowing them to focus on higher-value responsibilities. This is especially valuable in today’s environment, where labor shortages are a growing concern.

- Increased Productivity: The XP15 can boost productivity by up to 300% by ensuring that pallet transport tasks are done continuously, without delays. Automated transport reduces downtime, keeps workflows moving, and increases throughput.

- Quick and Simple Integration: Unlike many automation systems, XP15 doesn’t require a centralized IT system, making it a hassle-free choice for businesses without a complex tech infrastructure.

- Scalability: Whether you’re starting with one unit or planning to build a fleet, the XP15 can be scaled to meet your evolving needs. As your business grows, you can easily add units or enable advanced features like multi-stop routes and remote task management.

Real-World Applications: Who Can Benefit from XP15 AMR?

XP15 is a versatile solution ideal for various industries and applications, particularly for companies that already have automated systems like sorters, palletizers, or wrappers but lack automated transport between them. Here are some of the top use cases:

- Manufacturing and Production Lines: XP15 can transport parts to different production lines and pick up finished goods, creating a seamless flow between workstations.

- Warehousing and Distribution: For facilities that require efficient, repetitive transport across long distances, XP15 is a low-cost, high-impact solution.

- Order Fulfillment and Packaging: XP15 simplifies the movement of goods from sorting and packaging areas to palletizing and staging zones, ensuring faster and more organized workflows.

- Empty Pallet Transport: XP15 can also automate transport of stacks of empty pallets to storage (A-B transport), working as a basic automation tool in an experienced company with more automated processes, without disturbing the running process in start up.

- Waste management: XP15 can drive full containers to a carton press, and return with the emptied container, taking over no value added activity, freeing stuff to focus on more value adding tasks.

Ready to Take the Next Step?

If you’re ready to explore how the XP15 AMR can transform your warehouse operations, discover the success stories of businesses already benefiting from this powerful solution: XP15 Case Studies.

Unlock the power of automation and let the XP15 take your warehouse efficiency to the next level.