Implementation

Step 1: Let’s Connect!

Step 2: Site Survey

Step 3: Define Scope & Proof of Concept

Step 4: Delivery

Step 5: Follow up

Box-in-a-Box Solution

A standalone scheduling and storage solution designed for fast, easy implementation.

It supports a step-by-step path to automation:

-

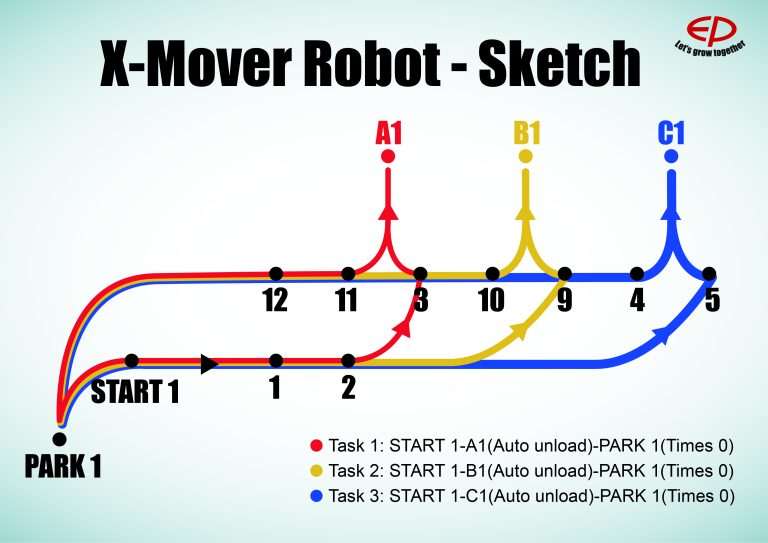

Material flow: Start with bottom-up automation by covering simple A–B or A–many transport using EXP/XP vehicles with fixed, proven logic. For many–many, high-chaos, or high-speed multi-truck operations, it scales to advanced fleet management.

-

Action flow: Operators trigger pick-up or drop-off tasks via PDA. The DAS system automatically handles routing and storage location decisions – and can run fully independent of any higher-level system.

-

Data flow: Integrate as much or as little as you want. Run completely offline as a “black box,” connect DAS + WMS for mixed manual/automatic operation and shared locations, or go for full integration including dashboards, a digital twin, or VR operation.

What’s Next?

Contact our team to add more machines and find more applications that can be solved with automation.

If you’re pleased with your robot and our automated solutions, we’d be happy to arrange additional customized solutions and functionalities.

Contact your Automation Team representative or click here to schedule a follow-up visit. We’re ready to support your automation growth!

Questions on uptime control? Telematics & EP Care