Other Industries Parts

EP CASTING

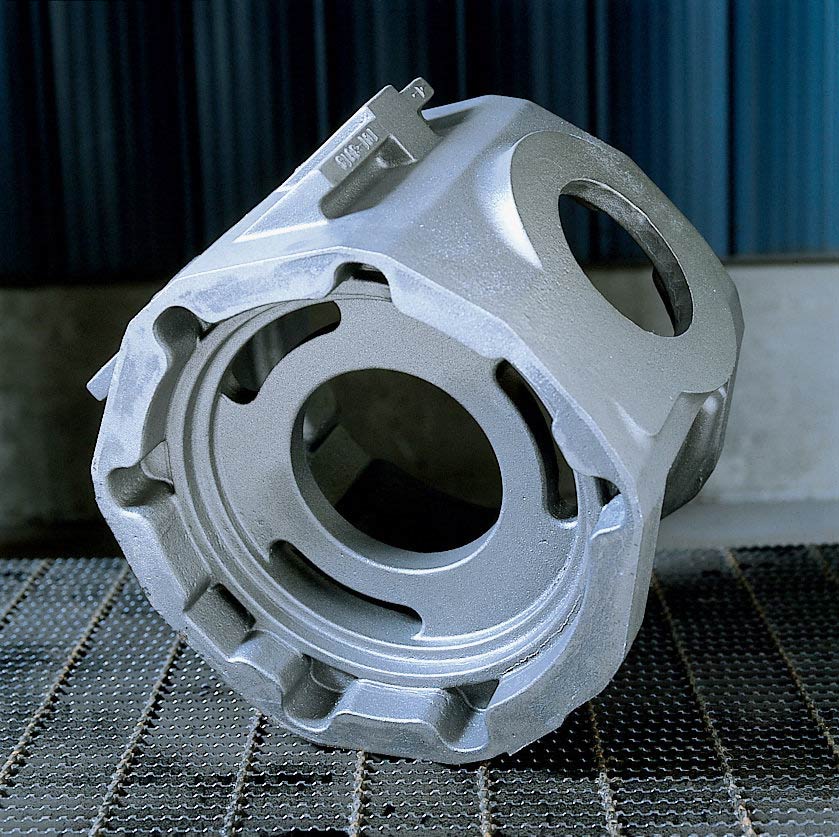

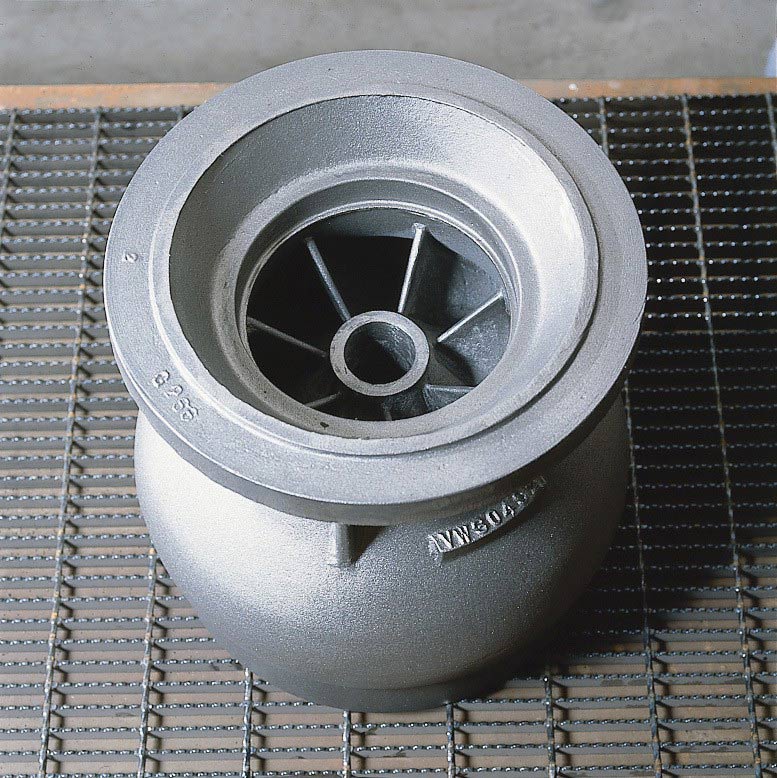

Examples of the casting parts we can offer

- Fuel dispenser parts for oil and gas retail stations

- HVAC and air compressor structural parts

- Mobile robotic parts for industrial applications

- Flanges & Joint Fittings

- Power tool parts

- Electric motor parts for various industries

Feature

Processing with supplied samples or drawings, EP combine the casting equipment with CNC machines to produce the durable parts for customers.

Materials

Aluminum, stainless steel, brass, copper, carbon steel, plastic (POM, PVC, PEEK, PU etc), alloy steel, titanium, Iron, spring steel, bronze.

Drawing format

PDF, DWG, CAD, DXF, STEP, IGS etc

Processing

Casting, CNC machining, CNC lathe/turning, 3/4/5 axis CNC milling, wire-cutting, EDM, grinding, Drilling, tapping etc.

Surface treatment

Anodized, heat treatment, painting, power coating, black oxide, silver/gold plating, electrolytic polishing, nitrided, phosphating, sandblasting, nickel/zinc/chrome/TiCN plated.

Quality control

100% full inspection for small QTY, ISO sampling inspection for mass productions.

Media Gallery

Contact Us

For any further questions, you can contact our sales team via email, WhatsApp or Linkedin. We will help you to find the right product for your application.