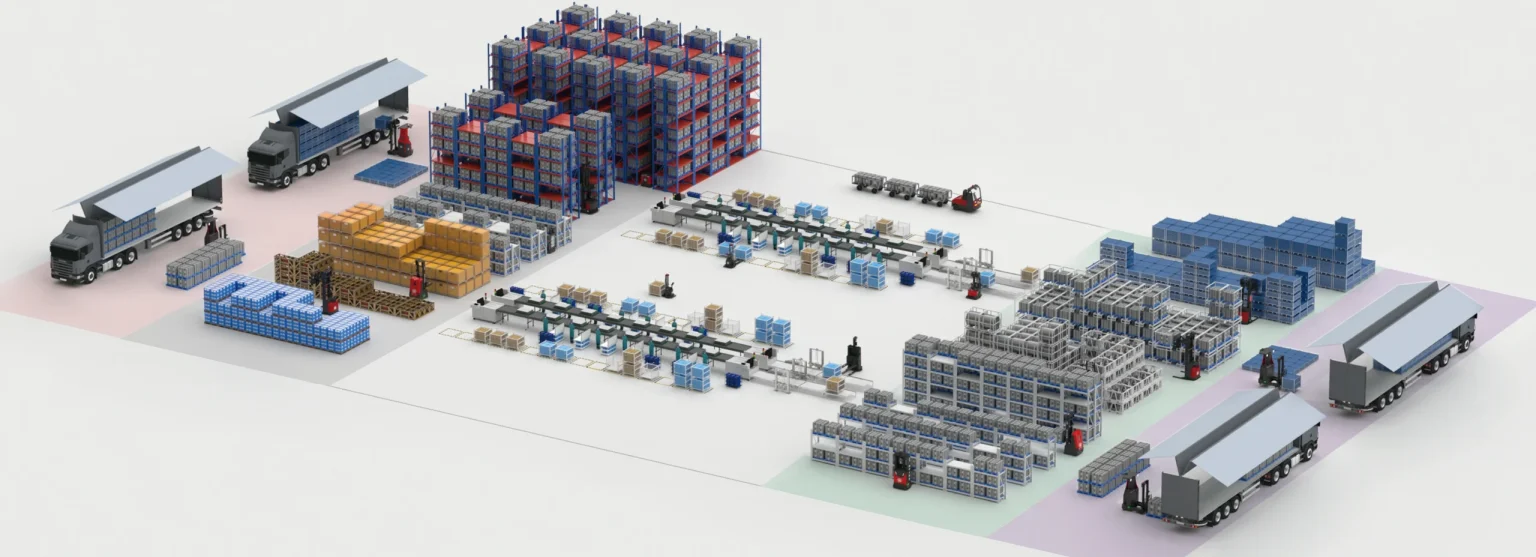

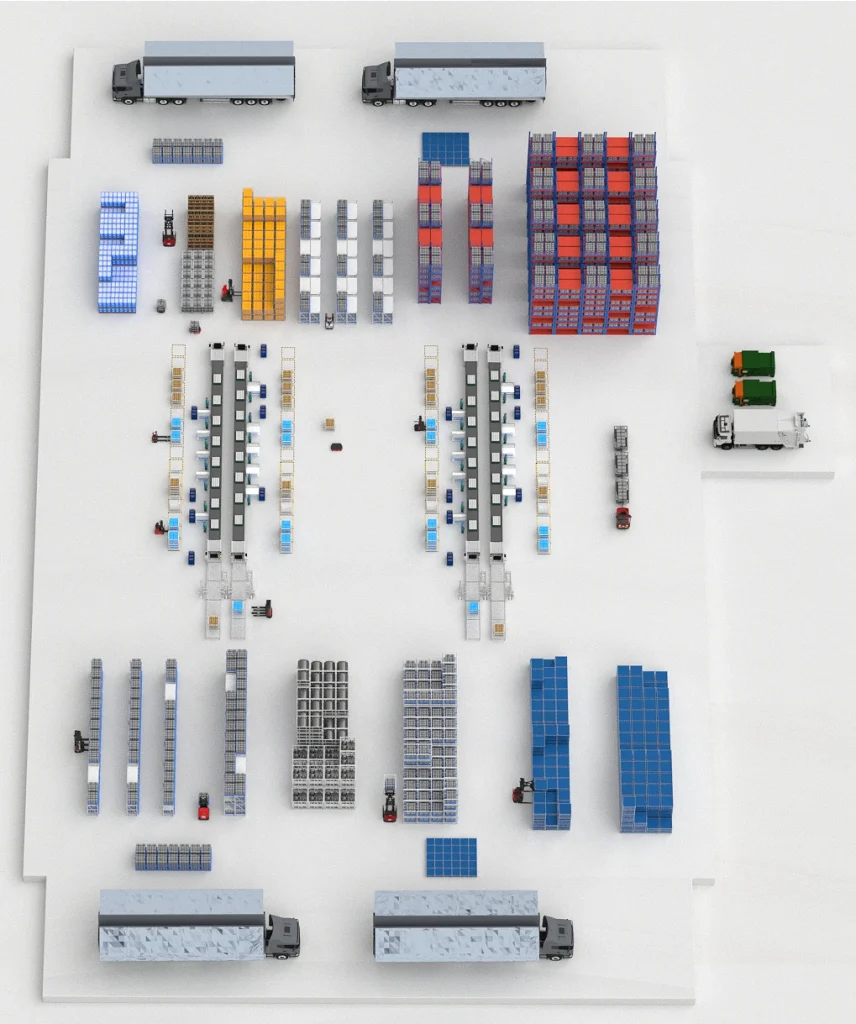

Transport Steps in Every Warehouse

Smarter Material Flow

We believe automation begins with understanding how materials move in your warehouse. Together with Arjan van Zanten, VP of Automation, we have developed a three-level strategy: starting with point-to-point transport, evolving to continuous-flow solutions like our “Sushi Bar” concept, and advancing to fully integrated, intelligent systems.

Whether it is inbound goods, production processes, or moving pallets from storage to outbound areas. These movements reveal where automation can have the greatest impact. By rethinking pallet transport, you can reduce manual handling, cut costs, and improve overall efficiency. It all starts by asking: where and how are you moving materials today?

1

Cross Docking

High speed cooperation between the operator and multiple pallet trucks

2

Incoming Goods to Storage

Transporting incoming goods to storage in front of racking areas.

3

From Storage to Production

Transport of parts to production and assembly lines.

4

Production Flow

Bring goods from one production area to the next.

5

From Production to Warehouse

Bring goods from the production machines to the warehouse

6

From Warehouse to Outbound

Easily transport goods from storage to your shipping, staging and outbound buffer storage areas

7

Rollerbed, Wrapper, or Sorter?

Do you have fixed handover points like rollerbeds, wrappers, or sorters?

8

Waste Collection & Empty Pallet Transportation

Everyone has waste, everyone has these routes, but who wants to do this activity all day?