X-Mover Technology

Three levels. One scalable path.

Warehouse automation doesn’t have to mean months of integration, expensive consultants, or ripping out what already works. EP Equipment’s autonomous solutions let you start small and scale at your own pace. Begin with simple, do-it-yourself pallet transport. Scale up to controlled fleets with smarter navigation and system integration. Then evolve to a fully connected Digital Autonomous System (DAS) with a real-time Digital Twin, unifying your entire operation.

Each level builds on the last, so you invest only when you’re ready and never more than you need.

Level 1

Offline automatic pallet trucks

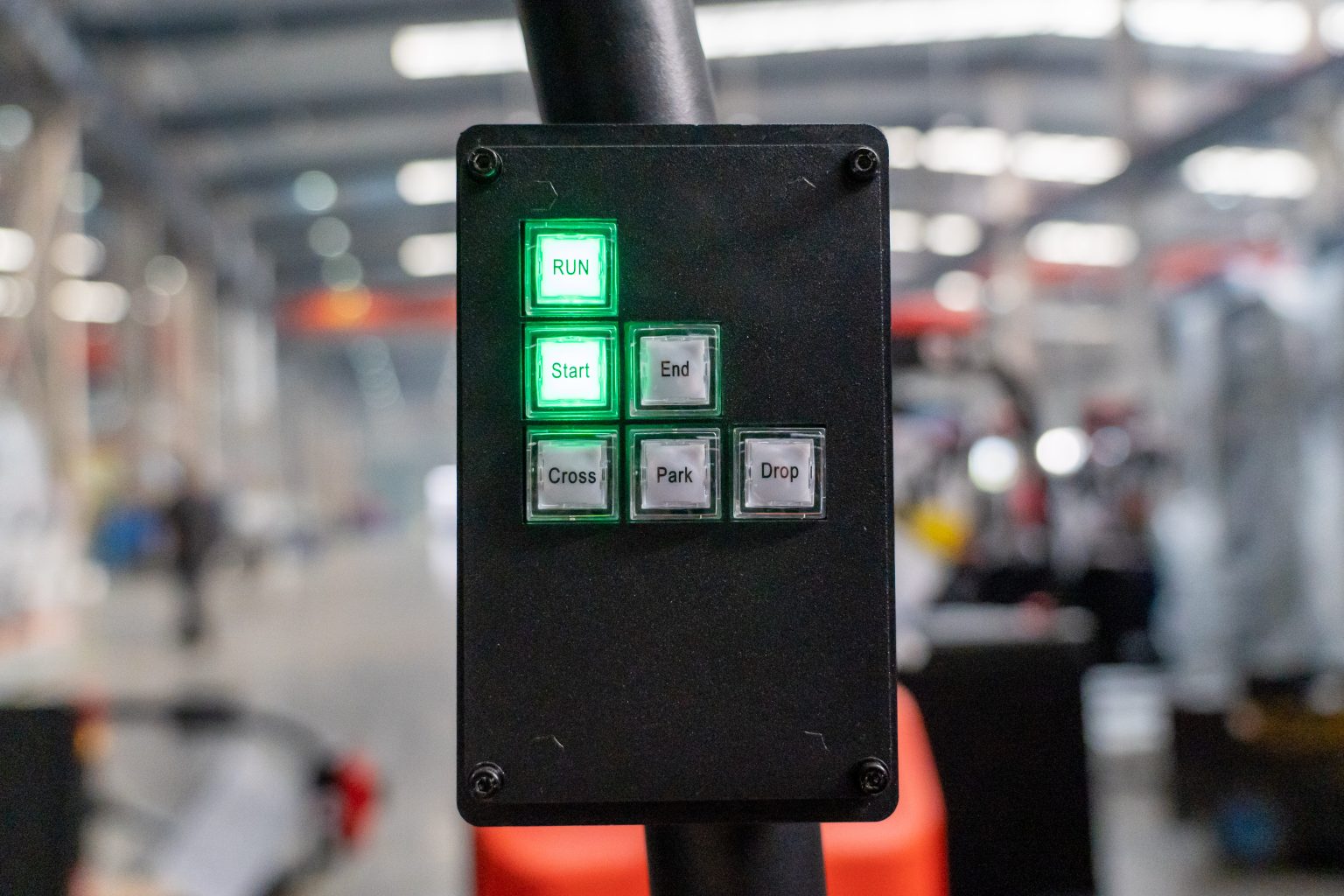

With our 5-button DIY installation, setup is quick and made for everyone plug in, press play , and you’re running.

-

Fast and easy implementation

-

Standard truck + navigation kit

-

Auto & Manual mode

-

Connect by Bluetooth

-

Set up by App or Keypad

Level 2

Autonomous solutions made simple

Standard task-based trucks as well as specialised solutions for loading, transport, stacking, and picking. Add smarter navigation, remote task control, and full system integration to your single-truck workflow. Features include SLAM, 3D vision, M2M communication, call box control, WiFi connectivity, traffic control, and WMS integration. Ideal for larger warehouses needing fast transport alongside dense, narrow stacking solutions.

Transport

Level 3

Integrated flow of material and data

Combine WMS, FMS, ERP, and autonomous scheduling into a single platform. Warehouse@Anywhere means move anything, store anywhere. From loading and unloading to transport, stacking, and cross-docking, X-Mover robots and DAS ensure full traceability and smooth pallet movement from storage to outbound.

Inventory is continuously optimised through automatic night-time reshuffling and FIFO logic, placing new stock at the back while moving fast movers to the front and slow movers further away. Dead stock is identified and sorted out dynamically, based on real-time data and AI logic. Transport jobs are prioritised automatically to optimise routes and reduce lead times.

With a 3D Digital Twin, you gain real-time visibility of stock and workflows, remote monitoring, and continuous optimisation – connecting the entire supply chain into one intelligent, end-to-end material flow

Digital Autonomous System (DAS)

DAS brings WMS, FMS, ERP, and autonomous scheduling into one intelligent platform – so material and data move as one. With X-Mover robots handling loading/unloading, transport, stacking, and cross-docking, you get smooth pallet movement and full traceability from storage to outbound. Powered by real-time data and AI logic, DAS continuously improves slotting, FIFO, and transport execution – keeping throughput high and travel low.

Key Benefits

-

End-to-end traceability across every pallet move

-

Automated FIFO + night-time re-shuffling to keep pick faces optimised

-

Dynamic storage optimisation: fast movers forward, slow movers back, dead stock identified

-

Priority-based job routing to reduce travel and boost throughput

-

3D Digital Twin for optimisation, remote monitoring, and real-time visibility

FAQs

How is DAS different from a traditional Warehouse Management System (WMS)?

Unlike a standard WMS that only tracks inventory, DAS also controls the physical movement of goods via robotics — it helps move, stack, and transport, not just record.

Can DAS work in any warehouse?

Yes. DAS is modular and scalable, meaning it can be added to existing warehouses or built into new projects. Whether you’re running a small storage space or a large distribution center, DAS adapts to your layout and workflow.

Do I need to replace my current systems to use DAS?

Not necessarily. DAS integrates with existing ERP/WMS (VDA 5050‑compatible) or can run stand‑alone. Start small and expand.